Introduction

Diesel generators play a crucial role in providing backup power in various applications, from hospitals and data centers to remote industrial sites. However, like any mechanical system, diesel generators are prone to failures that can disrupt operations and lead to costly downtime. Conducting a root cause analysis is essential to identify the underlying issues that contribute to these failures and implement effective solutions to prevent future occurrences. In this article, we will explore the importance of root cause analysis in maintaining the reliability and performance of diesel generators.

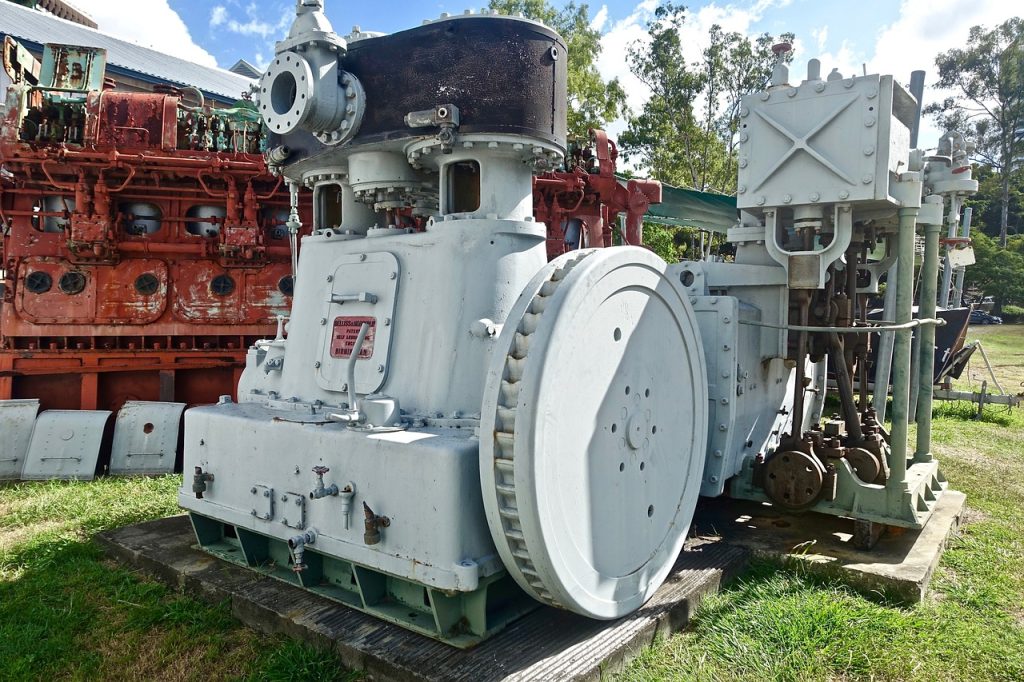

Overview of Diesel Generators

Diesel generators are a type of internal combustion engine that converts diesel fuel into mechanical energy to generate electricity. They are commonly used as backup power sources in situations where grid power is unreliable or unavailable. Diesel generators consist of several key components, including the engine, alternator, fuel system, cooling system, and control panel. These components work together to produce electrical power when the main power source fails.

Common Causes of Diesel Generator Failures

Diesel generators can fail for various reasons, ranging from mechanical issues to inadequate maintenance practices. Some of the common causes of diesel generator failures include:

1. Lack of Regular Maintenance: Regular maintenance is essential to keep diesel generators in optimal condition. Neglecting maintenance tasks such as oil changes, filter replacements, and inspections can lead to component wear and failure.

2. Fuel Contamination: Diesel fuel can become contaminated with water, dirt, or microbial growth, leading to fuel system issues and engine problems. Contaminated fuel can clog filters, injectors, and other components, affecting the generator's performance.

3. Overheating: Diesel generators rely on cooling systems to regulate engine temperature. Overheating can occur due to coolant leaks, clogged radiators, or malfunctioning thermostats, leading to engine damage and failure.

4. Battery Issues: Diesel generators use batteries to start the engine and provide power for control systems. Battery failures, such as sulfation, low electrolyte levels, or faulty connections, can prevent the generator from starting when needed.

5. Lubrication Problems: Proper lubrication is essential to reduce friction and wear in the engine components. Insufficient lubrication, contaminated oil, or oil leaks can lead to premature component failure and reduced engine efficiency.

Importance of Root Cause Analysis

Root cause analysis is a systematic process of identifying the underlying causes of problems or failures to prevent their recurrence. In the context of diesel generators, conducting a root cause analysis is crucial for several reasons:

1. Preventing Recurring Failures: By identifying the root causes of diesel generator failures, maintenance teams can implement targeted solutions to prevent the same issues from occurring in the future. This proactive approach helps minimize downtime and maintenance costs.

2. Improving Reliability: Understanding the underlying factors that contribute to diesel generator failures allows operators to make informed decisions to improve the reliability and performance of the equipment. Addressing root causes can enhance the overall operational efficiency of the generator.

3. Enhancing Safety: Some diesel generator failures can pose safety risks to personnel and property. Conducting a root cause analysis helps identify potential safety hazards and implement corrective actions to mitigate these risks, ensuring a safe working environment.

4. Optimizing Maintenance Practices: Root cause analysis provides valuable insights into the effectiveness of current maintenance practices and highlights areas for improvement. By focusing on addressing root causes, maintenance teams can optimize their maintenance schedules and procedures for better generator performance.

Steps in Root Cause Analysis for Diesel Generators

Conducting a root cause analysis for diesel generator failures involves a systematic approach to identify, analyze, and address the underlying issues. The following steps outline the process of root cause analysis:

1. Define the Problem: Clearly define the specific issue or failure that occurred with the diesel generator. Document the symptoms, impact on operations, and any relevant background information.

2. Gather Data: Collect relevant data and information related to the failure, including maintenance records, operating conditions, environmental factors, and any observations made by operators or maintenance personnel.

3. Identify Possible Causes: Brainstorm potential causes of the failure based on the available data and information. Consider both immediate causes (symptoms) and underlying causes (root causes) that may have contributed to the problem.

4. Analyze Root Causes: Use root cause analysis techniques such as the "5 Whys" method, fault tree analysis, or fishbone diagram to identify the primary factors that led to the failure. Look for patterns, trends, and relationships among the identified causes.

5. Develop Corrective Actions: Based on the root causes identified, develop specific corrective actions to address the issues and prevent future failures. These actions may include changes to maintenance procedures, equipment upgrades, training programs, or process improvements.

6. Implement Solutions: Implement the corrective actions in a timely manner to address the root causes of the failure. Ensure that all relevant stakeholders are informed and involved in the implementation process.

7. redirected and Evaluate: Monitor the effectiveness of the corrective actions implemented and evaluate their impact on the diesel generator's performance. Track key performance indicators (KPIs) to measure improvements in reliability, efficiency, and safety.

Case Study: Root Cause Analysis of Diesel Generator Failure

To illustrate the importance of root cause analysis in addressing diesel generator failures, let's consider a case study of a manufacturing facility experiencing recurrent engine shutdowns with its backup diesel generator. The facility relies on the generator to maintain critical operations during power outages, but the frequent failures have led to production delays and financial losses.

Problem Definition: The diesel generator consistently shuts down after running for a few hours, causing disruptions to the facility's operations and jeopardizing the safety of personnel.

Data Collection: Maintenance records indicate that the generator has been serviced regularly, and no major issues were reported during routine inspections. Operators report hearing unusual noises coming from the engine before each shutdown.

Possible Causes: Potential causes of the engine shutdowns include fuel contamination, overheating, lubrication problems, battery issues, or electronic control system malfunctions.

Root Cause Analysis: By conducting a thorough investigation using vibration analysis, oil analysis, and thermal imaging, the maintenance team identifies that the root cause of the engine shutdowns is a faulty fuel injector that is causing irregular combustion and engine misfires.

Corrective Actions: The maintenance team replaces the faulty fuel injector, flushes the fuel system, and conducts a thorough inspection of the engine components to ensure no further damage has occurred. They also implement a proactive maintenance schedule for fuel system checks to prevent similar issues in the future.

Monitoring and Evaluation: Following the corrective actions, the diesel generator operates without any further shutdowns, and the facility experiences improved reliability and operational continuity. The maintenance team continues to monitor the generator's performance and implements additional measures to enhance its reliability.

Conclusion

Root cause analysis is a valuable tool for identifying and addressing the underlying issues that contribute to diesel generator failures. By conducting a systematic analysis of the root causes, maintenance teams can implement targeted solutions to prevent recurring issues, improve reliability, enhance safety, and optimize maintenance practices. Through effective root cause analysis, organizations can ensure that their diesel generators operate efficiently and reliably, providing essential backup power when needed.